Digital Printing - The Facts

Table of ContentsOur Digital Printing DiariesIndicators on Digital Printing You Need To KnowThe Best Strategy To Use For Digital PrintingSome Of Digital PrintingDigital Printing - An OverviewExamine This Report on Digital PrintingThe Ultimate Guide To Digital PrintingThe Buzz on Digital Printing

Modification also allows businesses to stand apart in a congested market by developing one-of-a-kind advertising and marketing products that distinguish them from their competitors. Among the major advantages of digital printing is the capacity to publish variable data. Each printed item can be unique, allowing organizations to create tailored marketing products that speak directly to their target audience.Digital printing likewise permits personalization in the style of advertising materials. With digital printing, organizations can produce designs that are unique and customized to their particular needs. This can consist of customized graphics, typefaces, and designs that can help to separate them from their competitors. An additional advantage of electronic printing is the ability to publish as needed.

Getting My Digital Printing To Work

By publishing smaller sized quantities of marketing materials, companies can minimize waste and prevent the requirement for excess stock. Digital printing is additionally versatile.

By utilizing various products and layouts, organizations can develop special advertising products that stand out from their rivals and stand out from their target audience. Digital printing likewise provides consistency. With standard printing techniques, there is usually variant between prints because of differences in ink coverage, stress, and various other aspects.

This uniformity can aid build customer trust fund and credibility, revealing that business is committed to supplying premium materials. Uniformity is particularly essential for businesses that desire to develop customer depend on and integrity. By guaranteeing that every print corresponds, organizations can show that they are committed to supplying premium materials and taking notice of the details.

Excitement About Digital Printing

Furthermore, electronic printing produces less waste since it can print on demand and in smaller sized amounts, reducing the need for excess inventory and materials. Digital printing also makes use of much less power contrasted to typical printing approaches. Digital printers do not require as much energy to run, as they do not require to warm up as a lot or make use of as much power to run.

Some Known Factual Statements About Digital Printing

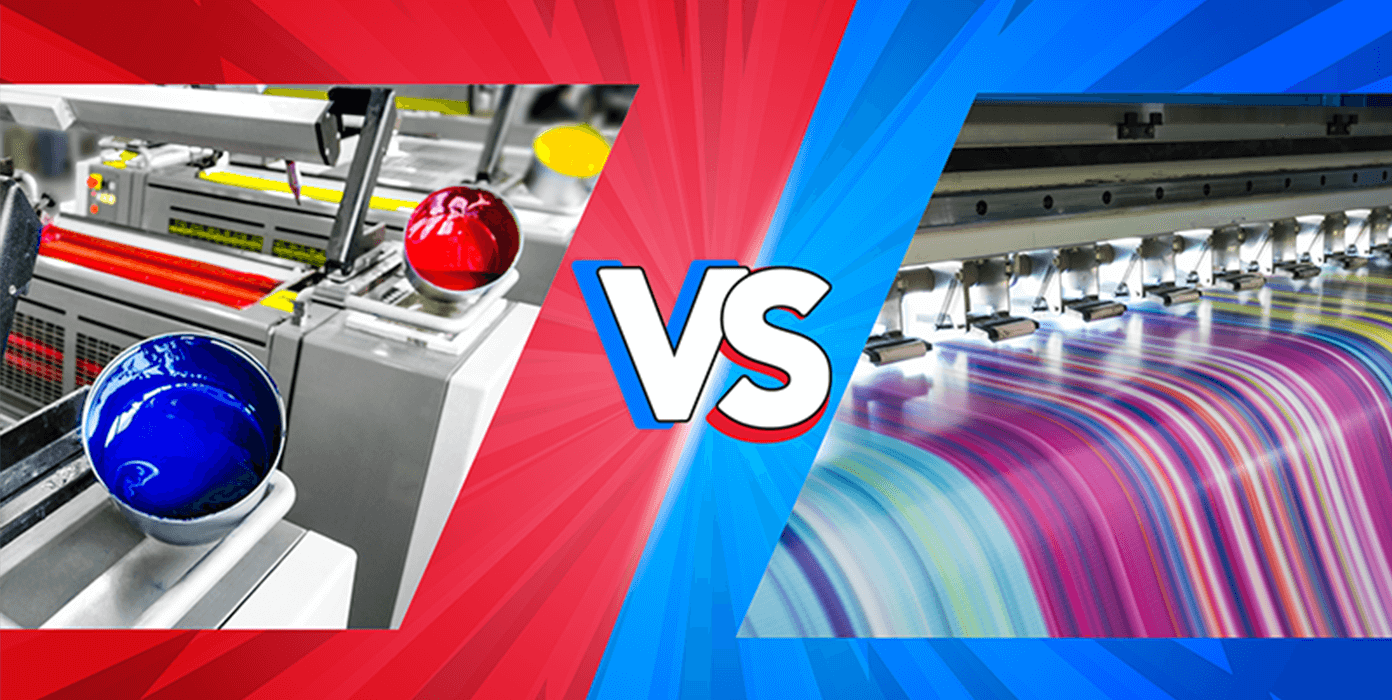

Balanced out printing requires a plate for each color printed. Conventional countered printing is a print approach that utilizes light weight aluminum plates to move ink onto a rubber sheet (usually referred to as a "blanket").

Digital Printing Fundamentals Explained

The equipment's set up expenses are high at first, additional units become reasonably much less costly as the quantity rises. Balanced out printing enables for a broad range of print products to be utilized during manufacturing. It enables the printer to utilize various paper kinds, custom-made surfaces, and various inks. The top notch photos created through countered printing make it the favored technique, particularly amongst visuals designers, when looking for the biggest color recreation, detail, and professional-looking prints.

For electronic inkjet printing, ink is transferred directly onto the surface area. Rather than depending on light weight aluminum plates and rubber blankets to transfer an image, digital printing utilizes fluid ink during manufacturing.

See This Report about Digital Printing

Because balanced out printing can blend custom-made color inks for each work, it will normally obtain the colors spot-on. Count on offset printing for tidy, unique types and images without touches or places.

It sets you back a lot to start an offset work. You need to invest money into developing home plates, which requires time. When you've spent it, all of the materials are prepared to go, and you'll invest less on big offset work than a digital print, which is regarding the very same per piece no matter just how huge the task gets.

Digital click for info printing is less pricey for low-volume jobs. The price per system drops for digital printing, so at some factor, they crisscross. Transforming information within a single print task.

Everything about Digital Printing

While electronic printing or inkjet printing is the recommended selection in the existing times, there are engaging factors to convert from balanced out to digital printing systems. When printing countered or electronically, vital decisions and procedures are included in color matching.

Whichever the case, the color will certainly need to be matched. Color matching of electronic printer ink is no more testing with dyes and pigments. Industrial inkjet printing supplies flexibility for printing on several substratums. Digital printing is suitable for clients who do not need longer runs and warehousing materials.

One advantage of digital printing is selecting from a wide array of electronic substratums. With electronic printing, the price of the substratum in the total job is minuscule.

The Best Guide To Digital Printing

drop-on-demand why not try here is the second printing innovation to think about. Continuous inkjet systems require significant maintenance, more operator training, and greater downtime. Nevertheless, devices costs in inkjet printing are far lower than offset printing as there are no plate-making, plates, and press expenditures. Past the capital expenditure, the prepress tools and printing machine require extremely knowledgeable drivers in offset printing, which adds labor prices.

Comments on “5 Simple Techniques For Digital Printing”